Fuses are an essential part of any electrical installation. They effectively protect the load and electrical systems against short circuits, overcurrent and overloads. Learn how to check if a fuse is blown and what to do if this happens.

Fuses are used in all electrical circuits – in building installations, electrical systems in vehicles, and electronics and household appliances. It is difficult to imagine effective protection of circuits and loads without breaking a circuit in the event of excessive current. Learn about the most common fuse types and find out how to test a fuse.

In this article you will learn:

Different types of fuses and their applications?

Fuses come in different types, which differ in design, performance and purpose. Among the most commonly used are fuses, thermal fuses, residual current devices, automotive fuses, PTC resettable fuses, SMD fuses, industrial and miniature fuses.

Fuses

A fuse is designed to break a circuit in the event of excessive current. Its essential component is a metal wire or strip (in some cases multiple strips of metal). How to check if a fuse is blown? To do so, it is necessary to check the condition of the fuse wire.

The relationship between the magnitude of the current that causes melting and the time needed for it to melt is given by the fuse’s melting time-current characteristics. Depending on response time, fuses can be divided into time delay and fast acting fuses.

The time-current characteristics, showing the correlation between current and time up to the melting of a fuse-element, are shown as bands. How to test a fuse? For this purpose, it is worth using the time-current characteristics and determining the current needed to blow a fuse.

With currents corresponding to the melting time less than 0.005 s (¼ cycle), the fuse limits the short-circuit current. In addition, they also act as disconnectors, since a permanent and visible break in the circuit is created when the cartridge fuse is removed or the fuse is unscrewed.

Low-voltage fuses are divided into general purpose fuses, high rupturing capacity fuses and special purpose fuses. Bi-type fuses consist of single-pole sockets, a bottom cartridge fuse, a head and a cartridge fuse inside. The rated currents of fast (BiWts) and slow acting (BiWtz) fuses are between 6 and 200 A. There are also medium acting and super-fast fuses on the market, such as SIBA 7000140.0.1.

Bu or Bm fuses provide higher rupturing capacity. The basic elements of their construction are jaws and cartridge fuses. They are used in transformer stations and large switchboards. They are used for the effective protection of machines with heavy and frequent start-ups, as well as for the protection of power lines.

The measuring instruments or loads are protected by fuses that conduct currents with intensity ranging from tens of milliamperes to several amperes.

Thermal fuses

Thermal fuses are designed to interrupt the circuit if the temperature rises to a dangerous level. They are primarily used to protect loads from damage caused by excessive system temperature.

When thinking about how to test a thermal fuse, keep in mind that they are often used to protect individual components of electrical systems - such as transistors.

Thermal fuses disconnect the circuit by melting a small meltable link, which releases the spring mechanism and separates the contacts. There are many thermal fuses on the market with a very wide range of disconnection temperatures, ranging from 72 to even 257°C. The disconnection temperature of ESKA 770.104 is 104°C.

Thermal fuses come in a variety of types. The most commonly used are thermal fuses, in which a fusible link (pellet) melts when a specific current passes through it. Bimetal thermal fuses, in which the bimetal bends in a specific direction if heated, disconnecting the current, are also available.

When the fuse cools down, the bimetal will return to its previous state, reconnecting the circuit. Bimetal thermal fuses are used, among others, in electric kettles.

How to check if a fuse is blown?

How to check if a fuse is blown?

When a fuse blows, it disconnects the circuit. How to test a fuse?

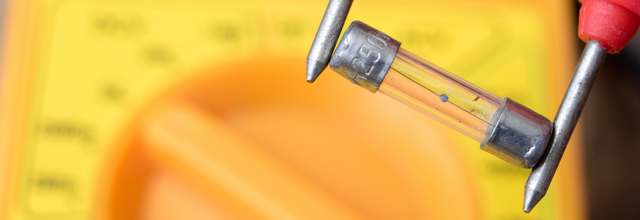

To check if the fuse is blown, use a multimeter. Set the multimeter on continuity mode. It may vary depending on the meter used but look for a rectifier diode symbol.

To test the fuse use a multimeter AXIOMET AX-MS8221B.

Plug the measuring leads in the multimeter - the red one into the VΩmA socket, and the black one into the negative (COM socket). How to test a fuse? Place the two test probes on the circuit to be tested.

Regardless of the fuse type, the measurement procedure is the same. So…how to test a fuse? In the case of automotive fuses, there are two blades on the top. Small fuses are measured by applying test probes to its both metal ends. Fuses have special recesses in the front part of the housing, which enable the measurement of circuit continuity.

If the circuit is continuous, the reading obtained should be a low resistance value. When the fuse is blown, the meter will indicate infinite resistance, nothing, or a lead failure with an acoustic and/or light signal. The blown cartridge fuse must be replaced with a new one with the same parameters and time-current characteristics. If other elements were also damaged, the entire fuse must be replaced.

How to test a thermal fuse?

How to test a thermal fuse?

How to check if a fuse is blown? The current flow through the thermal fuse should also be verified with a multimeter set on continuity mode. Similarly to fuses, the test probes should also be applied to the two conductive contacts of the fuse, checking whether the measurement value is low. If the meter beeps and/or lights or displays high resistance, the thermal fuse has blown and is not conducting electricity.

| Symbol: |

Description: |

| 7000140.0.1 |

Fuse; super-fast; ceramic; 100mA; 250V |

| 770.104 |

Thermal fuse; 10A; 250V; 12mm; 104°C |

| AX-MS8221B |

Digital multimeter; LCD 3.5 digits (1999) 15mm; 2.5x/s |